Tru Precision CNC

Right Parts on Time Every Time

Here at Tru Precision CNC we machine quality parts on time. This requires precise planning, advanced equipment, and skilled operators working in unison.

No matter if you need one part ,or thousands of parts a month we can help meet your needs.

Consistently delivering parts that meet exact specifications minimizes downtime and maintains production schedules.

We ensure customer satisfaction and operational efficiency.

Adhering to strict quality control standards throughout the machining process prevents defects and rework, while effective time management and workflow optimization guarantee on-time delivery.

Ultimately, the ability to produce high-quality parts promptly supports competitive advantage and strengthens supply chain reliability.

Our Equipment

A 3-axis CNC mill operates by moving a cutting tool along three linear axes. Known for high precision and accuracy, this type of milling machine is widely used for creating detailed parts with complex geometries, ranging from prototypes to production components. The three-axis configuration allows for effective control over depth, width, and length cuts, making it suitable for a variety of applications such as drilling, slotting, and contouring. Its straight-forward design offers reliability and ease of programming, which contributes to its popularity in industries including aerospace, automotive, and manufacturing.

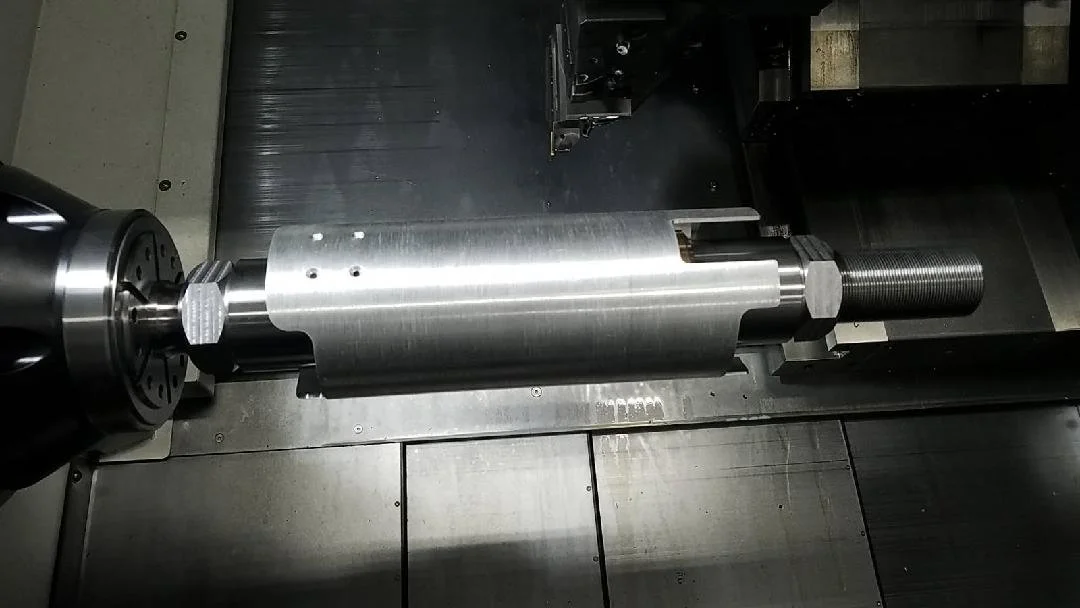

A live tooling 6 axis lathe is a highly advanced CNC machine that allows for complex, multi-axis machining operations in a single setup. Equipped with six axes of movement, including rotating and live tooling spindles, this lathe can perform turning, milling, drilling, and tapping without the need to transfer the workpiece between multiple machines. The live tooling feature enables the use of rotating tools powered independently from the main spindle, increasing efficiency and precision for intricate components. This combination of capabilities makes the 6 axis lathe ideal for producing high-precision parts with complex geometries, reducing cycle times, and improving overall productivity in industries such as aerospace, automotive, and medical device manufacturing.

About Us

We are a small family owned business that began by parents trying to teach their children the value of work. We started with a Bridgeport 3-axis knee mill, and sixteen years later we are running our own business with multiple CNC Machines.